Welcome

Processing

Our quality procedures begin with our partners and continue in our modern factory where complex production procedures are followed. Once all of the phases have been completed, the oil is stored according to IGP types, Italian and Biological.

01

the weighing

The weighing of the olives takes place after these have been stocked in bins. A form is completed containing information on our partner and characteristics of the olives (eg. If they have IGP or biological origin and their weight).

02

the debrancher

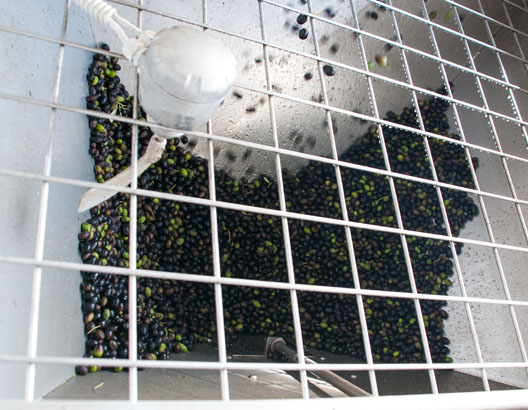

The previously stored olives are processed. This begins with debranching taking away branches and leaves and other external matter, such as metals thanks to magnet placed on the conveyor belt which also feed the cleansing procedure. The debranching procedure reduces the risk of residual pesticide and copper salts polluting the oil.

03

the washing

The olives are then carried on a conveyor belt which cleanses them eliminating any residual dirt thus assuring complete removal of pesticides especially those that are water-soluble.

04

the hopper

After the olives have been washed, they are passed onto a hopper that feeds the olive press with a cochlea. With this procedures the olives are processed and they are turned into a paste that is then transferred into kneading machine with the use of a pump.

05

the kneading

The kneading operation of the olive paste is necessary in increase the amount of oil extracted. This activity differs depending on the length and heated water temperature that circulates the outer sleeve of the machine

An oil is extracted cold when the kneading temperature does not go over 27 ºC. optimal kneading conditions are set when the processing time is about 30 To 60 minutes at a temperature of 30-32 ºC depending on the type of olive.

06

the decanter

Once the pre-established kneading time is complete, the paste is then transferred into a threephase decanter. At first the oil is separated from the waste material such as pomace and water,. This is done through a spin cycle separation allowing the residual water to be extracted from the oil and from the micro-fragments that accompany it.

07

storage

Our partners may either pick up the produced oil or confer it to the coo-op where it is stored according to the type (whether it will become IGP, Italian or biological). Our current potential stock is 40 tons stored in stainless steel vats in an appropriate location. The area is air-conditioned so that the product is well preserved. To avoid any deposit, the oil is poured from one container to the next when needed.

08

the oil

Usually, the processed and sold oil is not filtered,however, lately some partners have requested wee do so 9especially for the bottled oil) thus we now also provide this service.

Our guarantee

Top tree services

Expert advice

Suspendisse cursus ullamcorper fringilla. Vestibulum dictum at ipsum non placerat. Donec volutpat iaculis suscipit.

Cost savings

Suspendisse cursus ullamcorper fringilla. Vestibulum dictum at ipsum non placerat.

Time efficiency

Suspendisse cursus ullamcorper fringilla. Vestibulum dictum at ipsum non placerat.

Time efficiency

Suspendisse cursus ullamcorper fringilla. Vestibulum dictum at ipsum non placerat.